Beston charcoal making machine is not only a charcoal machine but also recycling equipment that turns biomass into energy. All the organic waste in the world can be used in the charcoal manufacturing equipment to get charcoal. Every country has plenty of biomass resources at present, so the extensively using of this kind of machine will be meaningful for the waste recycling industry in the local area.

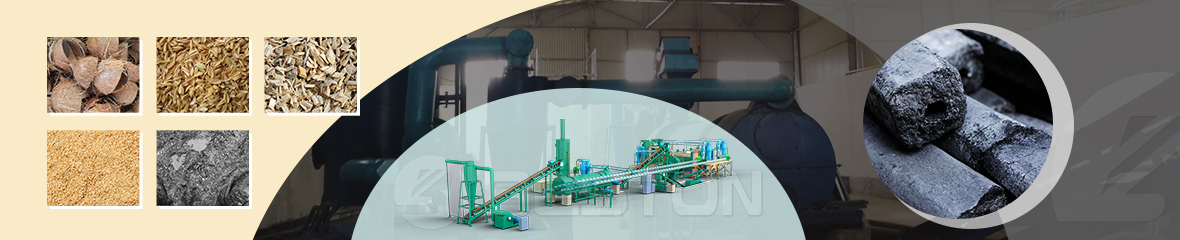

Feedstocks Acceptable by Beston Charcoal Production Machine

1. All organic waste in nature

2. Green waste (wood chips, branches, sawdust, bamboo, etc); agricultural waste (rice husk/hull, coconut shell, palm kernel shell, olive shell, coffee shell, straws, bagasse); human waste; kitchen garbage (mostly fruit peels); animal waste; etc.

3. Municipal solid waste (better with less than 5% inorganic matters )

Because the organic matters contain carbon, they can finally turn to be charcoal in a specific environment. That is the basic working principle for Beston charcoal making machine for sale. We adopt the high-end carbonization and pyrolysis technology, through drying, carbonizing, de-dusting, desulfurization, making charcoal from the above-said wastes. So you can also call it biomass carbonization plant.

So far, we provide 5 types of this machine:

| Item | Details | |||

| Model | BST-05 | BST-10 | BST-20 | BST-30 |

| Hourly Feeding Capacity | 500kg | 0.8-1 Tons | 1.5-2Tons | 2.5-3Tons |

| Working Method | Continuous | |||

| Raw Materials | 1.All kinds of biomass waste, such as sawdust, coconut shells, olive shells, palm shells, bamboo, etc. 2.Civil sludge, municipal sludge, industrial sludge, etc. 3.Municipal solid waste. |

|||

| Reactor Size | Φ800 | Φ1000 | Φ1300 | Φ1700 |

| Pattern | Horizontal & Rotary | |||

| Heating Materials | Charcoal, Wood, Diesel, Natural Gas, LPG, Biomass, etc. | |||

| Total Power | 40 kw/h | 55kw/h | 60kw/h | 72kw/h |

| Floor Area (L*W*H) | 30m*15m*7m | 35*15*7m | 45*15*10m | 50*15*10m |

| Operating Pressure | Constant Pressure | |||

| Cooling Method | Recycling Water Cooling | |||

| Life span | 5-8 Years | |||

Owing to the different contents and components of different feedstock, the final quality of bio charcoal will be different, which you can see the detailed comparison from the statistics below.

Comparison in Components of Charcoal from Different Feedstocks

| Item | Wood Sawdust | Rice Husk (Tianjin) | Rice Husk (Henan) | Coconut Shells (The Philippines) | Municipal Sewage Sludge |

| Moisture (%) | 6.84 | 5.12 | 6.09 | 9.1 | 1.02 |

| Bound Waste (%) | 4.51 | 2.59 | 3.58 | 4.19 | 0.66 |

| Ash (%) | 5.78 | 49.21 | 39.08 | 0.18 | 89.16 |

| Volatile (%) | 20.8 | 13.37 | 19.12 | 6.95 | 5.5 |

| Fixed Carbon (%) | 68.91 | 34.83 | 38.22 | 88.68 | 4.68 |

| Sulfur (%) | 0.08 | 0.17 | 0.12 | 0.09 | 0.77 |

| Max Heat Value (kcal/kg) | 6454 | 3396 | 3860 | 7277 | 706 |

| Min Heat Value (kcal/kg) | 6088 | 3127 | 3559 | 6724 | 566 |

What Can You Do with The Charcoal

Due to different components, the usage of those charcoal can be slightly different. But generally speaking, all of them can be used in the following aspects,

A. Fuel, e.g. the BBQ charcoal. For the increasing need of BBQ charcoal, this biochar production equipment for sale can be used as BBQ charcoal machine as well.

B. Producing carbon-based organic fertilizer for gardening or fast-growing woods.

C. Raw material to produce new-type water permeable bricks which can absorb rainwater, sewage and protect the underground water source.

Charcoal Manufacturing Process

The belt conveyor conveys the feedstock into the constant weight feeder, and the feeder feeds them into the carbonization host. Through the process of high-temperature carbonization, the charcoal is discharged through the sealed discharger. The combustible gas generated during carbonization will go through the cyclone de-dusting machine, spraying tower to receive filtering. And then go to the condensers, separating into tar and wood vinegar. The rest of the gas will be drawn into the exterior part of the carbonization host by the draft fan to supply heat for the carbonization process constantly.

The high-temperature residual gas can be used as the heat source for the drying system; the rest of residual gas will be filtered by de-dusting system, water spraying tower and then be discharged safely.

Note: when the water content of the feedstock exceeds 20%, the customer will need a drying host.

You can also refer to the coconut shell charcoal making machine video to learn details of the process.

Outstanding Advantages of Beston Charcoal Manufacturing Machine

Quality

- we adopt stainless steel 310S to the carbonization host.

- This material has a strong ability of high-temperature resistance and guarantees a long service life of the host.

Efficiency

- The whole working process of our charcoal manufacturing plant is fully continuous.

- The automatic discharging system makes a smooth and efficient carbonizing.

Green

- We use a strong filtering system to make sure the emission of residual gas is safe and meet the EU environmental emission standard.

- The fully sealed discharging system can make sure there’s no ashes and dust in the charcoal production line.

Beston Charcoal Making Machine Shipping to Ghana

Superior Charcoal Making Machine Design

Design for the Carbonization Host

Using gear wheel driving. Equipped with an end socket for feeding and discharging. The feedstock enters into the host through the feeding end socket, after the second-drying, enters into the cool area, warm area, high-temperature area, and hot area. The feedstock is carbonized in the cool area and then turns into charcoal which will be discharged by the sealed feeding system.

Design for the Drying Host

The upper layer of the drying host adopts dual drive infinitely variable speed structure with edge-transmission and central discharging. It enables the feedstock to form a “fog” like a storm in the flash steaming drying host, so as to quickly enlarge the contact area to the hot air.

Energy-saving Design

The machine has a combustible gas purification system. It can purify the combustible gas and then the gas can be used as fuel to the machine. As long as there’s plenty of combustible gas collected, the machine can totally rely on it. That will save much cost of fuel for the customers as well.

Beston- One of the Charcoal Making Machine Suppliers You Can Count on

Technology — Beston Group has a professional engineering and designing team with experienced engineers and technicians and a modernized workshop for the production line of the machine. We focus on technological innovation and got many domestic patents.

Supremacy at the International Market — the charcoal production equipment of Beston has covered a large percentage at the international market. You can see our charcoal machines in Kenya, Ukraine, Russia, Uganda, Australia, Turkey, and Spain, etc.

Competitive Charcoal Making Machine Price

Beston doesn’t only focus on the quality of the machine but also the cost of customers. Our charcoal machine prices are always affordable for those who really need it. We promise the prices and costs you spend on our charcoal making equipment will finally deserve.

Beston, as one of the leading suppliers of charcoal making machine in China, grasps the advanced technology, the best resources, and the strongest team of manufacturing, engineering, marketing, and service. Meanwhile, we’ll never forget the original intention to produce this machine, focus more on the improving of it and let more people in the world know the meaning of making charcoal from waste. You can also learn more about us on FaceBook.